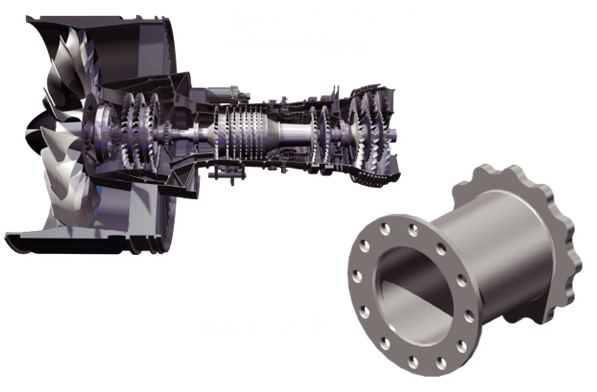

Can your precision machining meet the strict standards of the aerospace industry?

A 3-month practical diagnostic program using actual aero-engine part models (Ni-Alloy) to visualize your "Current Capability" and "Gap".

Entering the aero-engine industry requires massive investment and time.

Before committing to a full-scale entry, you need a low-risk opportunity to assess your potential.

We provide real materials (Nickel Alloy). Experience the full process: quoting, process design, machining, and inspection.

"Process Control" and "Documentation" are the biggest hurdles. Understand the high standards required by actually doing the work.

The evaluation report visualizes your strengths and gaps. It clarifies the specific challenges and resources needed for full entry.

Prototyping a nickel alloy component model (approx. Φ130mm). Includes not just machining, but also creating Process Sheets and Inspection Reports.

We strictly audit your part and documents from an aerospace perspective. You receive a feedback report with scores and improvement points.

*Sample Evaluation Chart